RICOH Ri 1000X a DTG & DTF machine

While DTG printing produces high-quality full size prints with brilliant colors and an incredibly soft hand feel, DTF printing definitely has some benefits that make it the perfect addition for your garment printing business.

Design

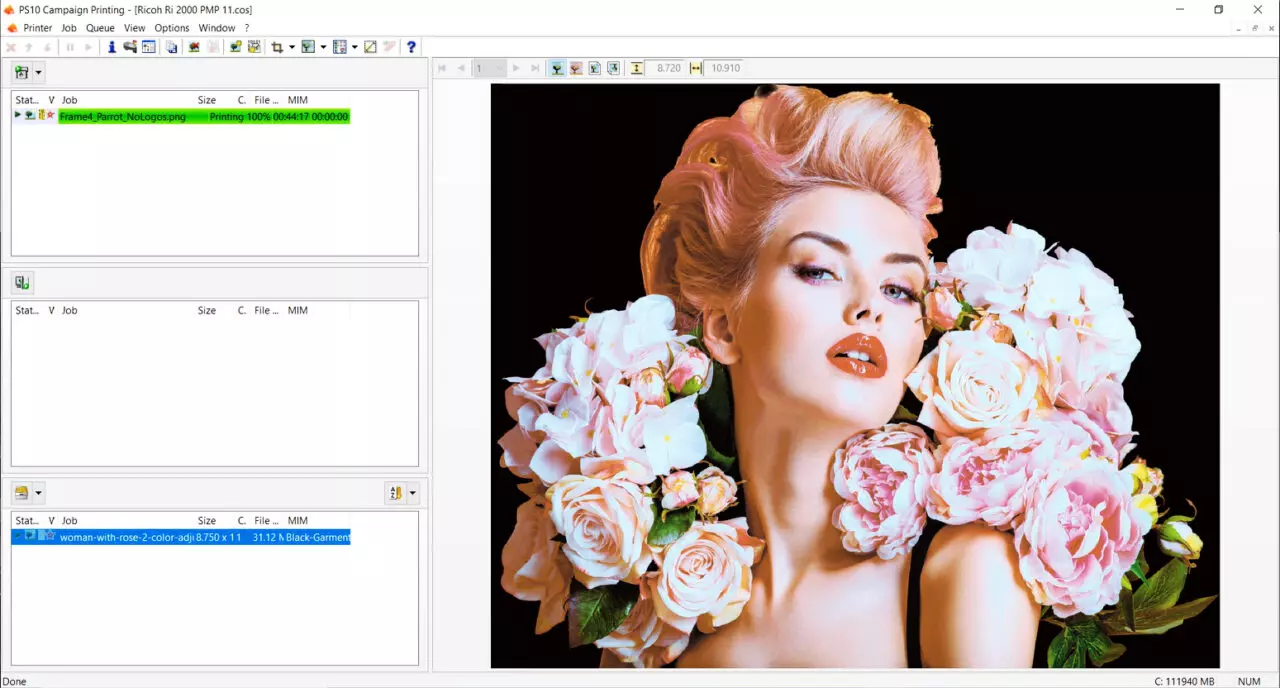

Once you have your image, prepare for print using the included ColorGATE software. Ricoh’s RIP software options help you get the perfect print by allowing you to position and fine-tune the image for the specific garment style and color.

And for DTF the only thing you have to change here is the layering order into C -> W, reduce the white amount and mirror your motif.

We also have a video tutorial for DTF. Check out the video here.

GOOD TO KNOW

DTF requires less white ink – about 40% white versus 200% white for DTG printing. White ink tends to be the most expensive since more of it is used, so reducing the amount of white ink used for your prints can be quite a money saver.

Place a DTF film on the printer and set the distance between the plate and the print head as small as possible. Now you can start the printing process.

During subsequent printing, the CMYK colors are applied first, followed immediately by a white top layer.

TIP: In the case of smaller motifs, of course, several graphics can also be printed on one film (e.g. to save space using the container function) and later cut out individually and transferred to the fabric.

Powdering

There are several ways to do this. For beginners, it is enough to do this manually. Sprinkle the powder evenly on the motif and then shake the film gently to remove excess powder.

TIP: The excess powder can be reused without any problems.

Cure

Once your print is complete and powdered with adhesive glue, it has to be cured in an oven or under a heat press by hovering. Curing time and temperature will vary depending on the adhesive, film and ink.

Easy Application

The transfers are now ready to be pressed onto the chosen product. With DTF you can place your design on hard-to-reach or awkward surfaces and have a wide variety of materials like cotton, nylon, treated leather, polyester, 50/50 blends.

TIP You can also prepare the transfers and store them for up to 6 months.