Transform inspiration into reality with the new RICOH Ri 1000 direct to garment printer. Our versatile, next-generation machine provides quick print speeds and crisp, vibrant graphics.

Whether you need to fulfill an order for hundreds of customized t-shirts or a single, highly personalized one-off, printing custom garments requires only three easy steps: design, print, and cure.

Design

If you can design it, you can print it. Create your graphic using your favorite design software, such as Photoshop, Illustrator, or CorelDRAW. If you prefer, you also can print graphics accepted from customers or other designers as long as they submit the image in PNG, JPG, or TIFF formats.

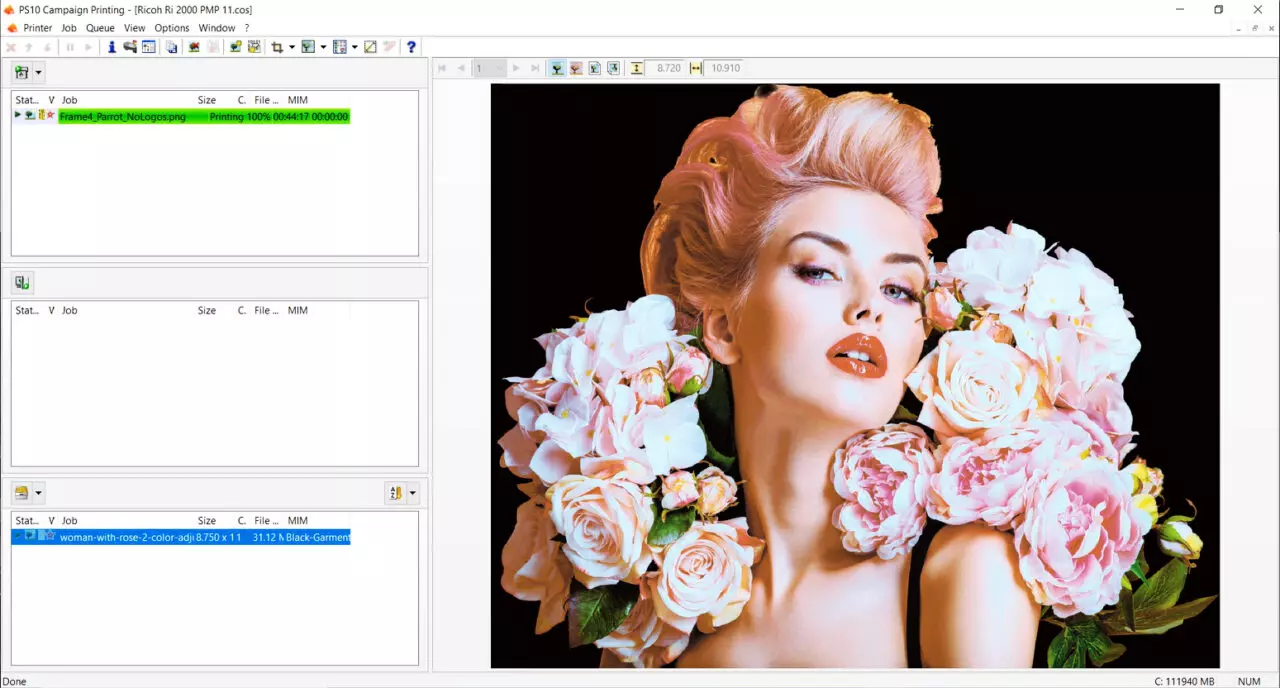

Once you have your image, prepare for print using the included ColorGATE software. Ricoh’s RIP software options help you get the perfect print by allowing you to position and fine-tune the image for the specific garment style and color.

Whether you are printing on light garments or dark garments, an adult-size t-shirt or extra-small infant onesie, the RICOH Ri 1000 creates gorgeous, eye-popping prints quickly. Our water-based inks are not only environmentally friendly and cost effective, but they also allow you to print on both natural fabrics and synthetic blends like 100% light poly.

When you’re ready, simply load your garment and send your file directly to the printer or to a USB drive for convenient printing.

Cure

Once your print is complete, it is essential to cure the ink into the fabric to ensure a long-lasting printed garment that is easy to clean in a regular washing machine, less likely to fade, feels soft, and resists cracking when stretched. Cure your printed garment using a heat press or tunnel dryer.