Print directly onto 100% polyester with built-in Enhancer

Design

If you can design it, you can print it. Create your graphic using your favorite design software, such as Photoshop, Illustrator, or CorelDRAW. If you prefer, you also can print graphics accepted from customers or other designers as long as they submit the image in PNG, JPG, or TIFF formats.

Once you have your image, prepare for print using the included ColorGATE software. Ricoh’s RIP software options help you get the perfect print by allowing you to position and fine-tune the image for the specific garment style and color.

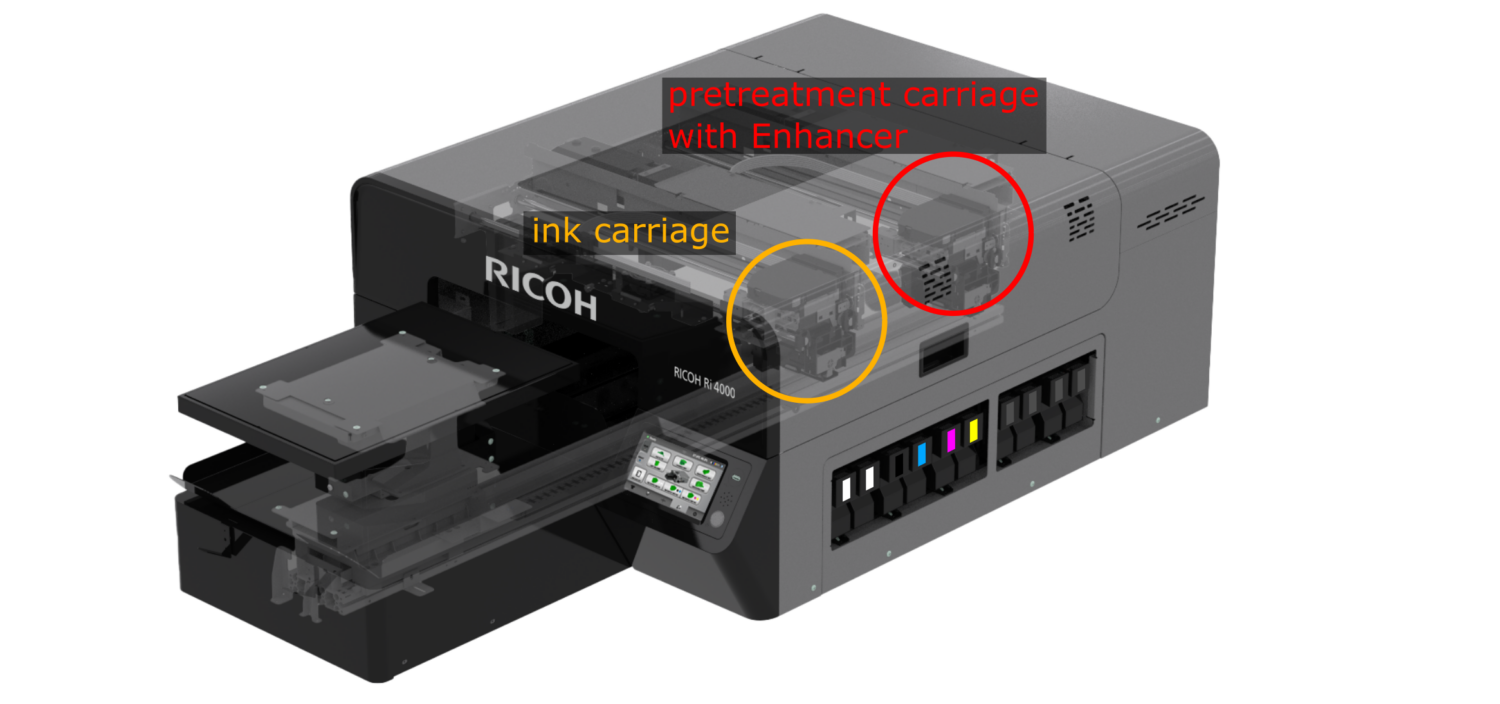

Inbuilt Pre-treating process

Dual ink carts for pretreatment and printing. The first ink carriage applies our Enhancer. The second carriage applies our environmentally friendly CMYK and White water based pigment inks.

For light-colored polyester garments, enhancer is not required.

When you’re ready, simply load your garment and send your file directly to the printer or to a USB drive for convenient printing.

The new inkjet enhancer prints directly onto polyester. The enhancer saves time by pre-treating the garments inside the machine.

Ricoh’s inks are safe, durable and bright. And they now deliver stunning results on polyester.

Cure

Once your print is complete, it is essential to cure the ink into the fabric to ensure a long-lasting printed garment that is easy to clean in a regular washing machine, less likely to fade, feels soft, and resists cracking when stretched. Cure your printed garment using a heat press.

Dark polyester: 120 seconds at 120°C

White polyester: 120 seconds at 160°C

Dark cotton: 120 seconds at 160°C

White cotton: 120 seconds at 160°C

(Heat press, conveyor times vary)